what is QFD? (quality function deployment)

To thrive in business designing products and services that excite the customer and creating new markets is a critical strategy. And while growth can be achieved in many different ways--selling through different channels, selling more to existing customers, acquisitions, geographic expansion-- nothing energizes a company more than creating new products or upgrading existing products to create customer delight.

Quality Function Deployment (QFD) is a methodology for building the "Voice of the Customer" into product and service design. It is a team tool which captures customer requirements and translates those needs into characteristics about a product or service.

The origins of QFD come from Japan. In 1966, the Japanese began to formalize the teachings of Yoji Akao on QFD. To thrive in business designing products and services that excite the customer and creating new markets is a critical strategy. And while growth can be achieved in many different ways--selling through different channels, selling more to existing customers, acquisitions, geographic expansion-- nothing energizes a company more than creating new products or upgrading existing products to create customer delight.

Quality Function Deployment (QFD) is a methodology for building the "Voice of the Customer" into product and service design. It is a team tool which captures customer requirements and translates those needs into characteristics about a product or service.

The origins of QFD come from Japan. In 1966, the Japanese began to formalize the teachings of Yoji Akao on QFD.

Since its introduction to America,

QFD has helped to transform the way businesses:

- plan new products

- design product requirements

- determine process characteristics

- control the manufacturing process

- document already existing product specifications

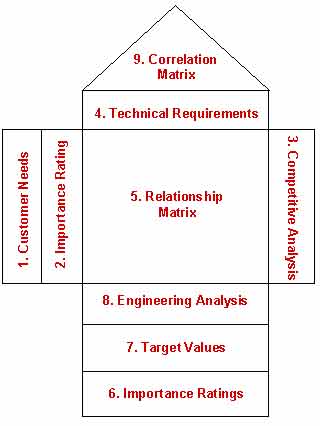

QFD uses some principles from Concurrent Engineering in that cross functional teams are involved in all phases of product development. Each of the four phases in a QFD process uses a matrix to translate customer requirements from initial planning stages through production control.

Each phase, or matrix, represents a more specific aspect of the product's requirements. Binary relationships between elements are evaluated for each phase. Only the most important aspects from each phase are deployed into the next matrix.

Phase 1-Led by the marketing department, Phase 1, or product planning, is also called The House of Quality. Many organizations only get through this phase of a QFD process. Phase 1 documents customer requirements, warranty data, competitive opportunities, product measurements, competing product measures, and the technical ability of the organization to meet each customer requirement. Getting good data from the customer in Phase 1 is critical to the success of the entire QFD process.

Phase 2- Phase 2 is led by the engineering department. Product design requires creativity and innovative team ideas. Product concepts are created during this phase and part specifications are documented. Parts that are determined to be most important to meeting customer needs are then deployed into process planning, or Phase 3.

Phase 3-Process planning comes next and is led by manufacturing engineering. During process planning, manufacturing processes are flowcharted and process parameters (or target values) are documented.

Phase 4-And finally, in the production planning, performance indicators are created to monitor the production process, maintenance schedules, and skills training for operators. Also, in this phase decisions are made as to which process poses the most risk and controls are put in place to prevent failures. The quality assurance department in concert with manufacturing leads Phase 4.

QFD is a systematic means of ensuring that customer requirements are accurately translated into relevant technical descriptors throughout each stage of product development. Meeting or exceeding customer demands means more than just maintaining or improving product performance. It means building products that delight customers and fulfill their unarticulated desires. Companies growing into the 21st century will be enterprises that foster the needed innovation to create new markets.

|